What is a polyurethane tooling board?

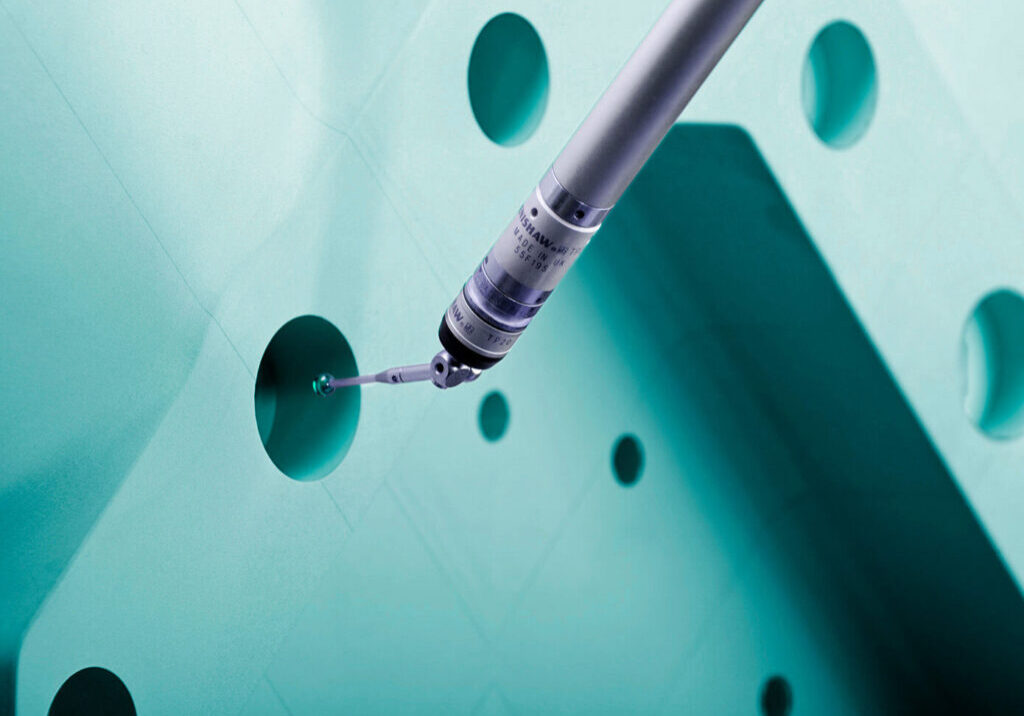

A polyurethane tooling board is a machinable block of material, designed for the production of patterns, prototypes, master models, fixtures, jigs and other tooling applications.

Polyurethane boards can be bonded together to create larger blocks and CNC machined or hand styled to meet the requirements of the application.

Standard sizes and custom options

Our polyurethane tooling boards are available in a range of standard board sizes with thicknesses between 50 mm and 200 mm, giving you flexibility to match your project's requirements.

If your application demands something outside these standard dimensions, custom sizes can be arranged to suit your exact specification. Just let us know what you need, and we'll work with you to deliver a made-to-measure solution.

FIND THE RIGHT PRODUCT FOR YOUR APPLICATION WITH OUR INTERACTIVE SELECTOR TOOL

Due to its versatility, durability and cost-efficiency, polyurethane tooling board material is favoured for a wide range of applications.

Why use a polyurethane tooling board?

Typically more cost-effective, polyurethane tooling boards are perfect for use in lower-temperature applications. They are stable and easy to mould, producing a great surface finish.

The material is lightweight and versatile, making it suitable for both hand styling and CNC machining. When machining, excess material flakes rather than produces dust.

How Polyurethane tooling boards streamline production

Polyurethane tooling boards aren’t just popular for their versatility—they also deliver significant benefits when it comes to efficiency and material usage.

- Material Efficiency: With excellent machinability and minimal waste, you get more usable product from each block.

- Faster Processing: Because our boards machine cleanly with minimal chipping or dust, you can cut down on post-machining cleanup time.

- Reduced Production Time: The ease of shaping, combined with the stable nature of the material, means faster milling and modelling—particularly important for time-sensitive projects.

The result? An overall smoother, speedier process that helps you deliver on deadlines without compromising on quality or cost control.

Key Features

- Easy to work with, producing high-accuracy results

- Superior dimensional stability

- Great surface finish

- Abrasion-resistant materials available in our high-density range*

- Wide range of densities available from 80 kg/m3 to 1,700 kg/m3

*Our high-density PU range exhibits on average 52% less wear than our medium-density PU range. Based on internal Taber testing - for more details and test results please get in touch.

APPLICATIONS

- 80 kg/m3 to 450 kg/m3 low-density PU boards are designed for use in design, styling and prototyping projects

- 600 kg/m3 to 850 kg/m3 medium-density PU boards are designed for use in automotive modelling, vacuum forming, thermoforming, jigs and fixtures and foundry applications

- 1,100 kg/m3 to 1,785 kg/m3 high-density PU boards are designed for use in specialist applications including, vacuum forming, thermoforming, hammer or metal forming, jigs and fixtures, foundry patterns and core boxes, and Reactive Injection Moulding (RIM).

Ancillary products

We offer a full range of specially formulated, compatible ancillary products to meet your manufacturing needs.

These ancillary products include:

To ensure seamless results and optimal performance, our adhesives and repair pastes are designed to work perfectly with our full range of polyurethane boards. Standard board sizes are available, and we can also supply custom sizes to meet specific project requirements.

Whether you’re bonding, sealing, finishing, or repairing, our ancillary products help you achieve high-quality results.