Working with you, we can create simple or complex near-net-shape tooling, at our facility in Leicester, UK, ensuring your tool is as close to the final shape and size as possible. This reduces the amount of post-production machining and finishing required, saving you time and resources and resulting in less waste material.

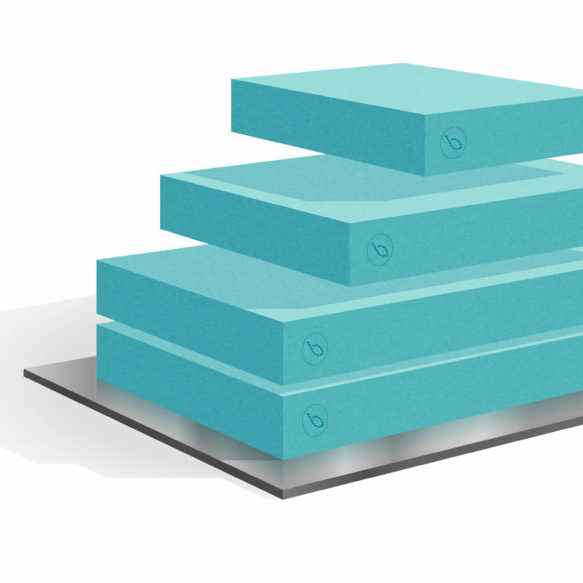

Using your CAD drawings and designs, first we create a bespoke negative mould for your tool using one of our industry-leading, low-density polyurethane materials. We then select the system for casting based on your application and requirements and use the negative mould to cast your near-net-shape tool.

We have a range of materials available for mass casting applications and near-net-shape tooling, with densities ranging from 600 kg/m3 to 1,700 kg/m3.

FIND THE RIGHT PRODUCT FOR YOUR APPLICATION WITH OUR INTERACTIVE SELECTOR TOOL

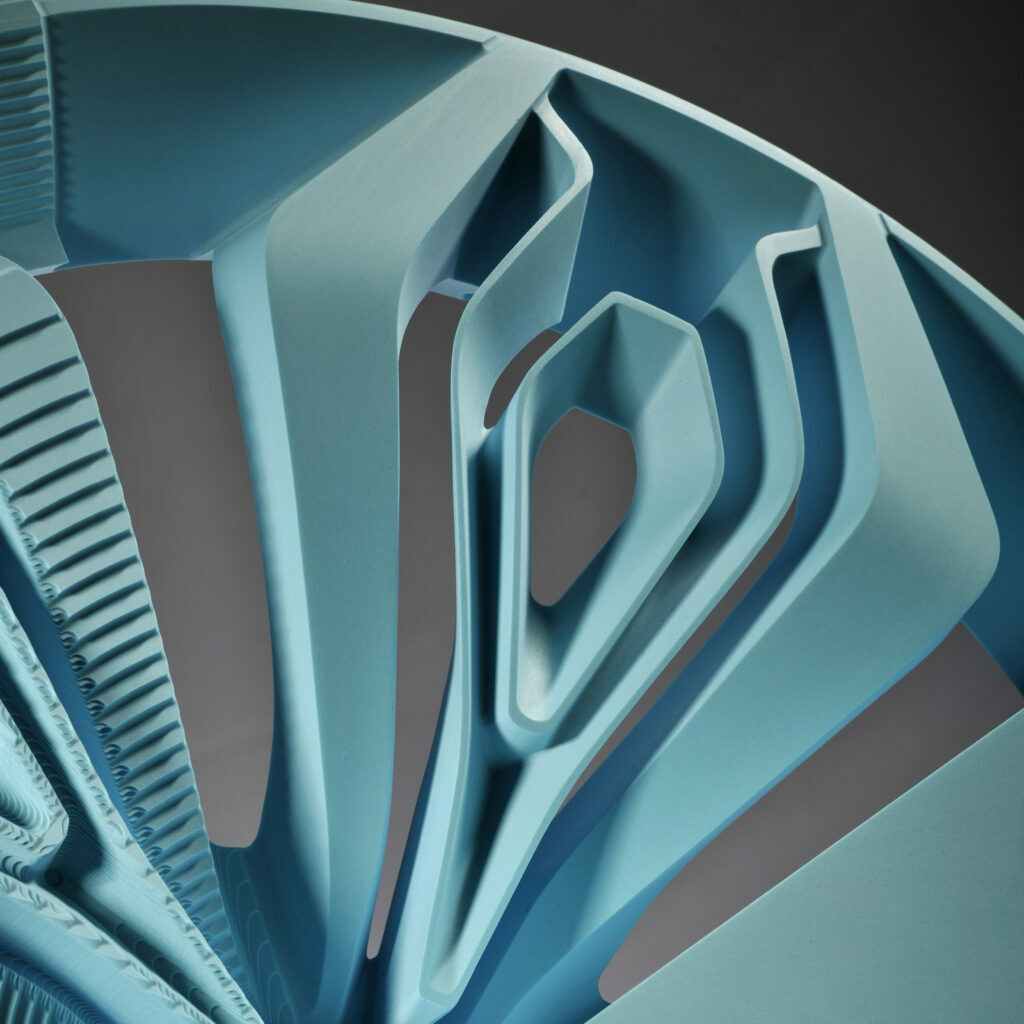

Our mass casting service offers increased flexibility when designing and producing complex geometries and intricate details.

Through optimal material usage and reduced energy consumption compared to traditional CNC machining, mass casting can contribute to lowering your overall carbon footprint.

FEATURES & BENEFITS

- Reduction of waste material through near-net-shape casting

- Reduced production costs at near-net-shape tool needs less machining

- Tool is cast as a single piece, there are no visible bond lines

- Processing savings as service is outsourced

- UK-based manufacturing service

APPLICATIONS

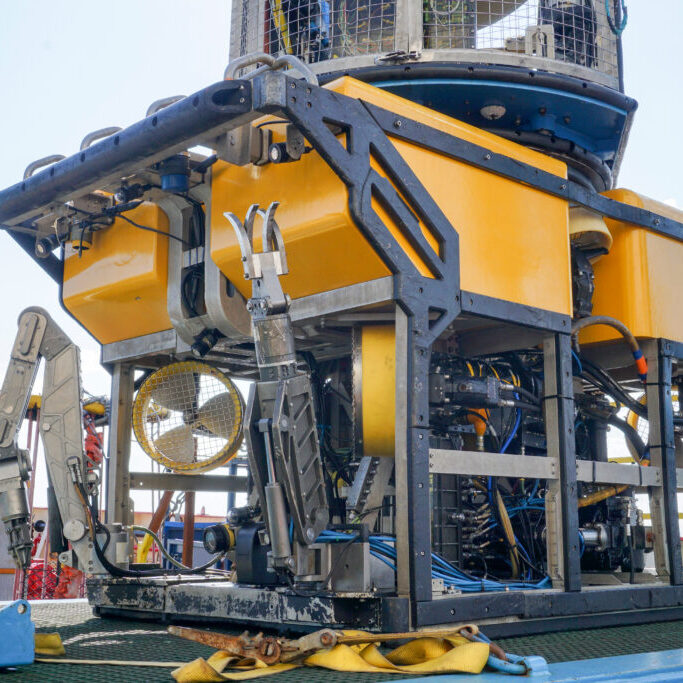

- Complex geometry tooling

- Intricate detail tooling

- Single-piece tooling

- Large scale tooling

- High-temperature applications