Designed with customers in mind, our wide range of subsea buoyancy materials provide maximum uplift for a given volume, with some of the lowest-density materials available for applications from shallow water down to full ocean depth.

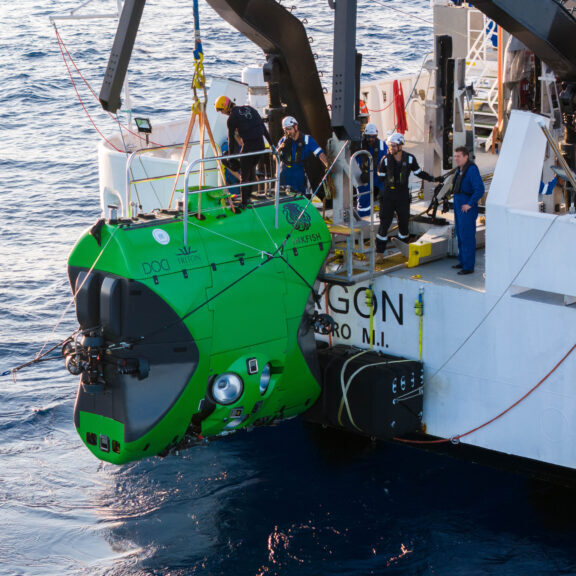

We understand the need for high-performance, reliable solutions, especially when engineering buoyancy for crewed subsea vehicle applications. And for added peace of mind, our complete range of Subtec ® materials has DNV approval of manufacture.

Subtec® high-performance, low-density syntactic buoyancy materials

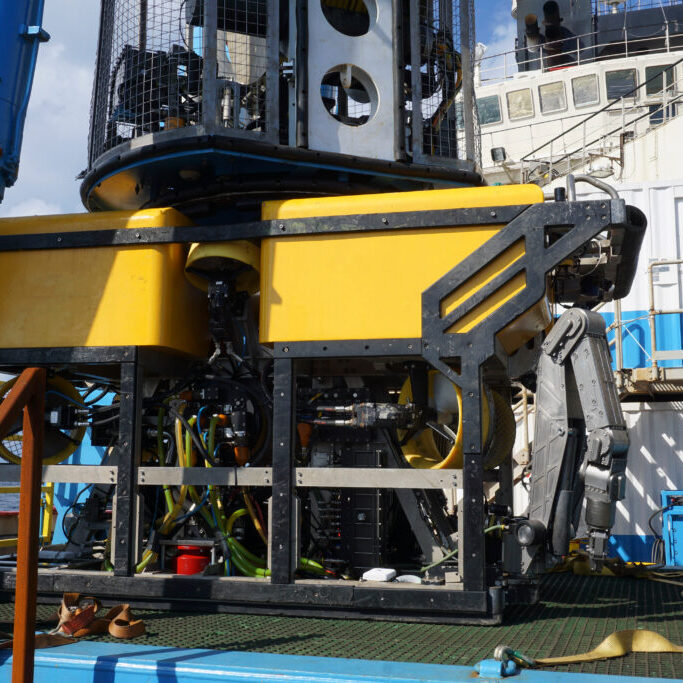

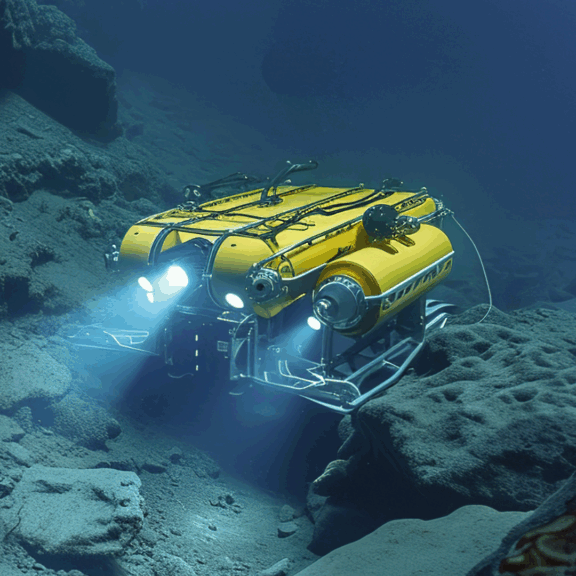

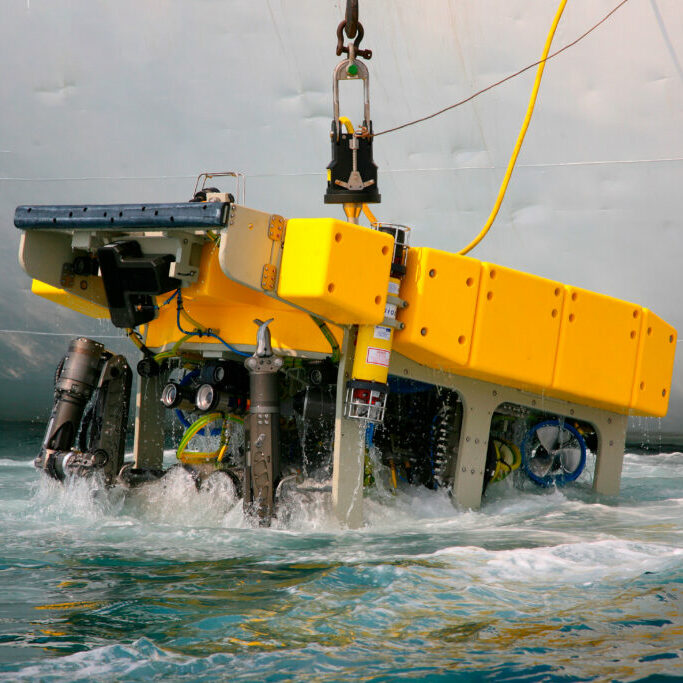

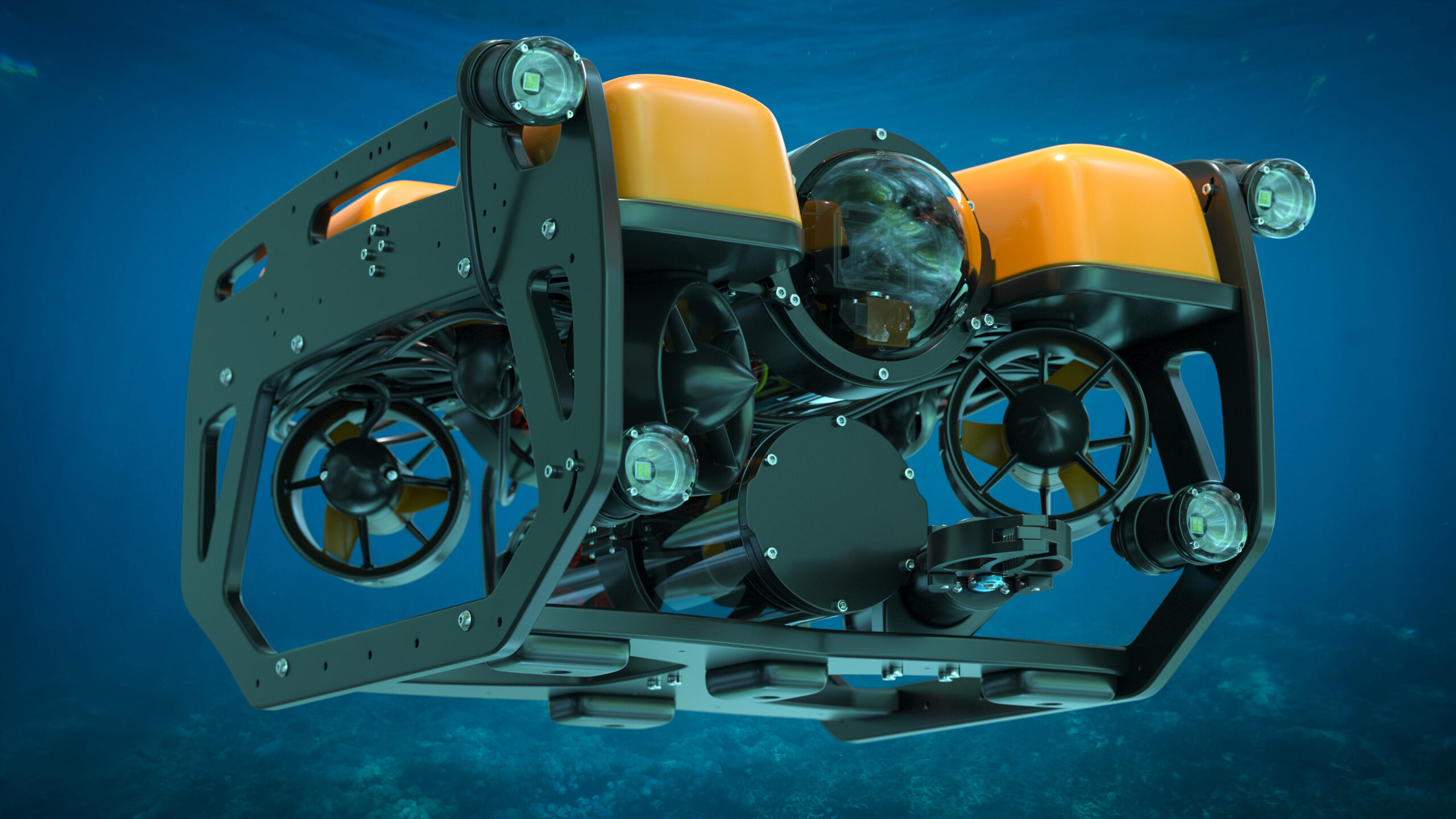

Base Materials range of DNV-accredited Subtec® subsea buoyancy materials is engineered for use in applications including remotely operated vehicles (ROV), autonomous underwater vehicles (AUV) and human-operated vehicles (HOV), and qualified for use in seawater depths down to 11,500 metres.

Comprising high-grade hollow glass microspheres and a novel thermoset polymer matrix, our low-density Subtec® buoyancy materials are formulated to produce ultra-high strength-to-weight characteristics with excellent water ingress resistance. This makes them the ideal solution for subsea applications including crewed and uncrewed vehicles.

Shallow water buoyancy materials

Our range of materials engineered specifically for shallow water vehicle applications ensures you have an alternative solution for depths of 100 to 1,000 metres seawater.

Manufactured from copolymer foam, our shallow water buoyancy materials are easy to machine and shape to meet your application requirements.

Finished modules and assemblies or material blocks

Working as an extension of your team, finished buoyancy modules are manufactured to exact specifications and drawings at our purpose-built facility in the UK, with the option for the addition of a protective coating for impact and abrasion resistance, aesthetic paint finishes and custom markings.

Our materials are cast into standard block sizes ready for use and shaping by your in-house team. Blocks can be bonded together and machined to create buoyancy modules to meet your application requirements.

An alternative approach: Buoyancy repair and refurbishment

Designed to give you a way to revive old, damaged or worn buoyancy modules, giving them a second life and providing you with an alternative solution, extending service life to ensure you get maximum usage and reducing waste to landfill.

This unique service includes the repair of any scuffs, cracks, splits or chips; replacement of missing sections, damaged edges or damaged inserts; repainting and recoating to your exact specifications. All works are completed using approved materials and processes and finished to industry-recognised standards.