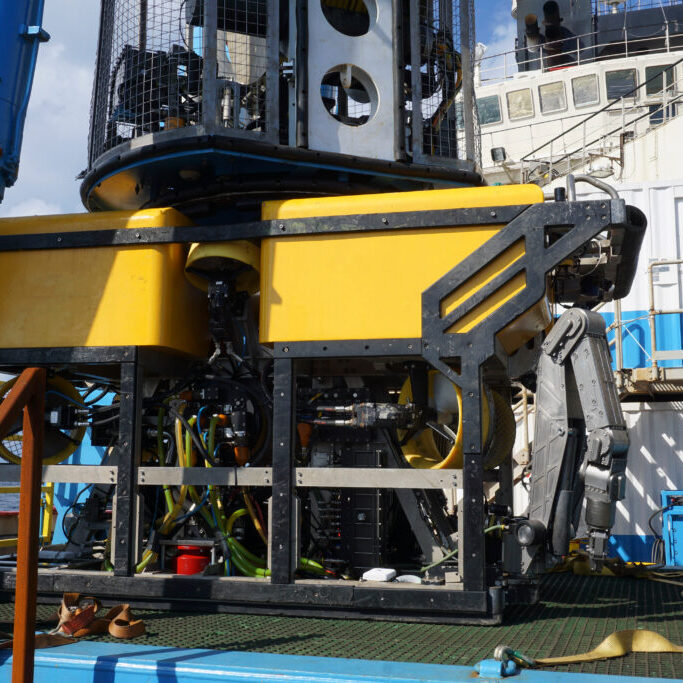

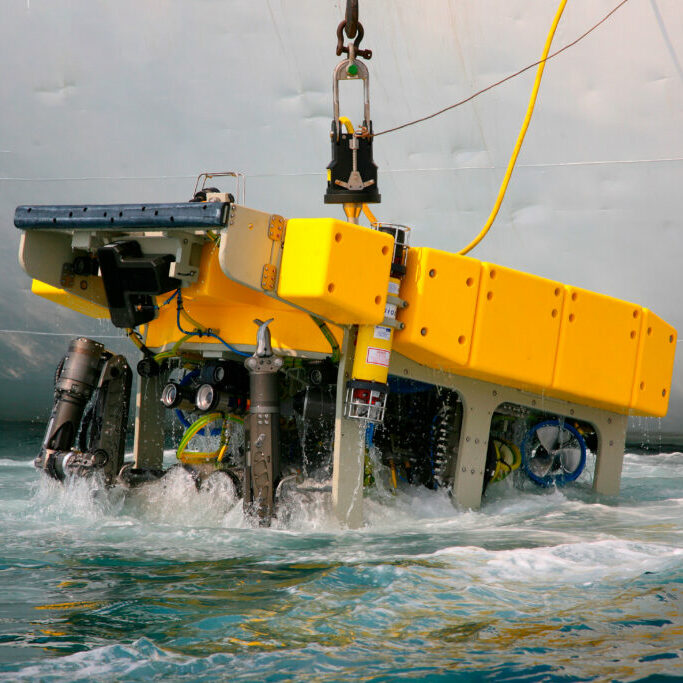

As the global energy mix continues to tilt towards renewables, offshore wind is playing an increasingly central role in driving sustainable power generation. But behind the towering turbines and sprawling offshore arrays lies a vast and often invisible support infrastructure - one that’s becoming increasingly strained as demand outpaces the availability of vital subsea equipment, especially remotely operated vehicles (ROVs).

ROVs - crucial to the installation, inspection, maintenance, and repair of offshore wind assets - are in short supply. Many of the ROVs originally built for oil and gas projects are being repurposed for renewables work, and while this helps alleviate pressure in the short term, it’s far from a long-term solution. The sheer scale of projected offshore wind development, especially in deeper waters, is exposing a growing gap in ROV availability - one that’s driving a surge in both refurbishment and new-build programmes.

As new-generation ROVs enter service and older models are upgraded or retired, attention must turn to the performance of their mission-critical components — including buoyancy modules. These ensure stability and performance at depth, enabling ROVs to carry out essential work efficiently, safely, and reliably.

Driving demand: Renewables, deeper waters, and the electrification of ROVs

Several intersecting trends are reshaping subsea operations. Beyond the rapid growth of offshore wind, including floating wind in previously unviable deeper waters, traditional oil and gas operators are also ramping up activity - widening existing field footprints, revisiting brownfield sites, and extending operations into deeper zones once considered unviable.

Together, this surge in activity has placed a strain on the global ROV fleet. The renewables sector alone is responsible for a significant portion of the increase in demand, and as a result, new ROVs are being built at a much faster pace. At the

same time, the industry is seeing a shift toward electrification - moving away from legacy hydraulic systems toward lighter, more efficient, and environmentally sustainable electric-powered ROVs.

Whether building from scratch or upgrading legacy units, the emphasis is the same: improved efficiency, enhanced durability, and verified performance at depth. That’s where material certification and testing become mission critical.

Why buoyancy modules must be tested and certified

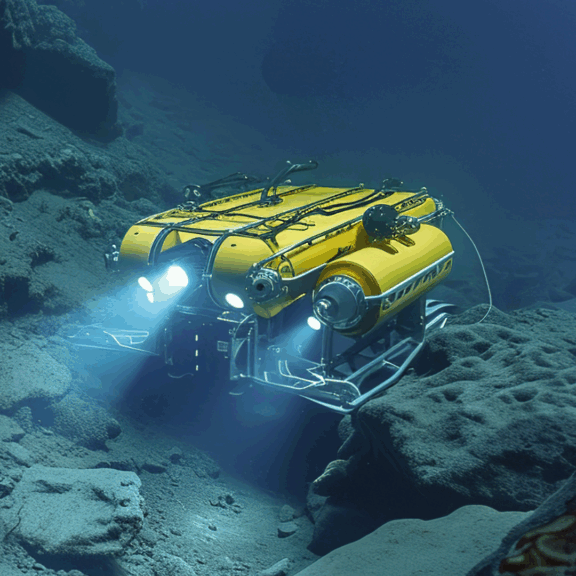

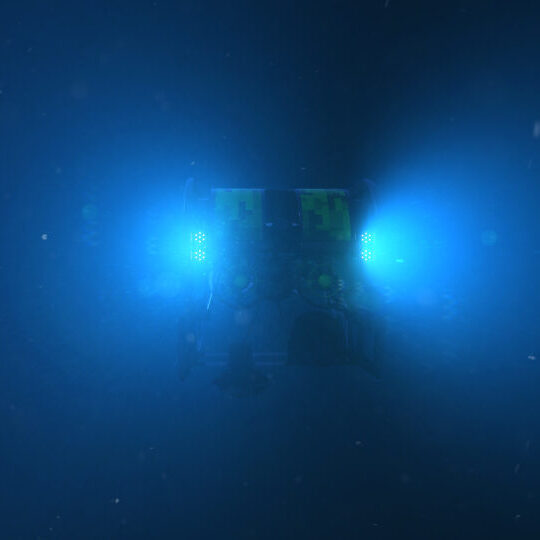

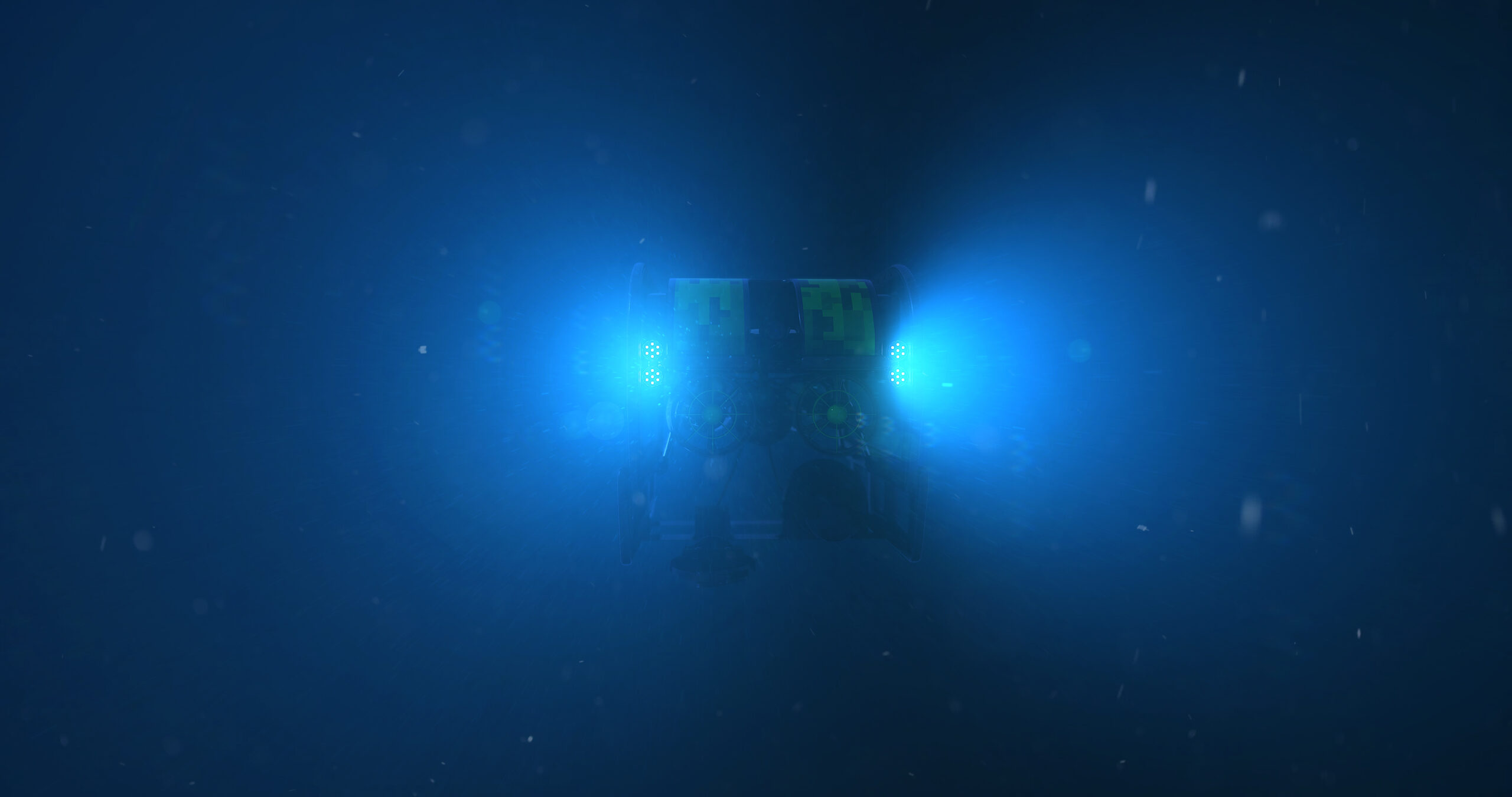

In the race to meet the growing demands of offshore renewables, the reliability of every subsea asset becomes critical. As the operational envelope of offshore renewables expands into deeper waters, more remote locations, and harsher conditions, it’s vital that the buoyancy materials used can match the demands of modern ROV missions.

ROVs are essential to the installation and upkeep of these facilities, and buoyancy modules play a vital role in enabling those ROVs to perform safely and efficiently.

Buoyancy modules are not passive components; they are engineered systems designed to perform under extreme pressure, often for prolonged periods. If they fail, ROVs can lose their ability to maintain stable positioning, increasing the risk of collisions, mission failures, or even total vehicle loss. With operations often taking place in remote environments, even minor setbacks can lead to major delays, and financial and environmental impacts.

To ensure performance under such conditions, buoyancy materials and modules must be subjected to rigorous testing. This includes evaluating their water absorption properties. If a material absorbs water over time, its buoyancy will reduce, leading to a compromise in its ability to function correctly. Controlled water absorption testing helps quantify and mitigate this risk.

Another critical test is hydrostatic crush pressure, which simulates the extreme pressures found at operational depths. This test helps establish the depth rating of the material - in other words, the maximum depth at which it can function without structural failure. Without this validation, it's impossible to guarantee the materials’ integrity in deep-sea deployments.

Density and compressive strength testing are also essential. These characteristics directly affect how much buoyant force the module provides and how it holds up under the physical stresses of deployment, handling, and long-term immersion. Materials that are too dense may not provide adequate uplift; and conversely those that are too weak can deform or fail under these conditions.

Testing extends beyond the materials to the buoyancy modules themselves. Accurate weight-in-air and weight-in-water measurements are used to verify that modules provide the precise level of buoyancy specified in the vehicle’s design. These measurements are crucial in ensuring neutral or slightly positive buoyancy, which allows the ROV to hover and manoeuvre effectively without using excess energy.

In addition, dimensional inspections, often carried out using laser scanning, ensure that the physical form of the module matches original design specifications. Even small deviations can result in an unsatisfactory fit, uneven load distribution, or hydrodynamic inefficiencies - all of which can impact the ROV’s performance.

Despite the importance of these factors, the reality is that many manufacturers still carry out this testing internally without independent oversight. While many are well-equipped and experienced, this practice opens the door to inconsistencies - especially when there is no industry-wide requirement for third-party verification or for the testing equipment itself to be audited. In a high-risk, high-stakes industry like offshore energy, such gaps should not be ignored.

The case for independent testing and certification is therefore both practical and strategic. When ROVs are tasked with enabling billion-pound infrastructure in harsh and remote offshore environments, operators cannot afford to take chances on unproven components. Robust, standardised, and independently verified testing of buoyancy modules ensures that these unseen but essential components deliver the safety, reliability, and performance needed to support the energy transition at sea.

DNV type approval: A benchmark for confidence

While not a regulatory requirement, DNV type approval has become an established industry benchmark for verifying the quality, durability, and performance of subsea buoyancy materials. As the world’s leading classification society for the maritime and offshore sectors, DNV provides independent validation of a material’s suitability for challenging subsea environments - an especially important factor as ROV operations extend further offshore and into deeper waters.

The type approval process subjects buoyancy materials to a comprehensive suite of laboratory tests and quality audits, examining key properties such as mechanical strength, water absorption, density, and hydrostatic pressure resistance.

These assessments ensure that materials consistently meet stringent performance standards, helping ROV designers, operators, and end users reduce risk, improve reliability, and support long-term performance in critical subsea roles.

For the fast-growing offshore renewables sector, the assurance provided by DNV certification can be a vital differentiator. In high-cost, high-risk operational environments, independent third-party approval supports decision-making and underpins confidence in equipment performance, especially when deploying into increasingly deep and remote locations.

Case study: Maintaining the DNV classification of DSV Bakunawa

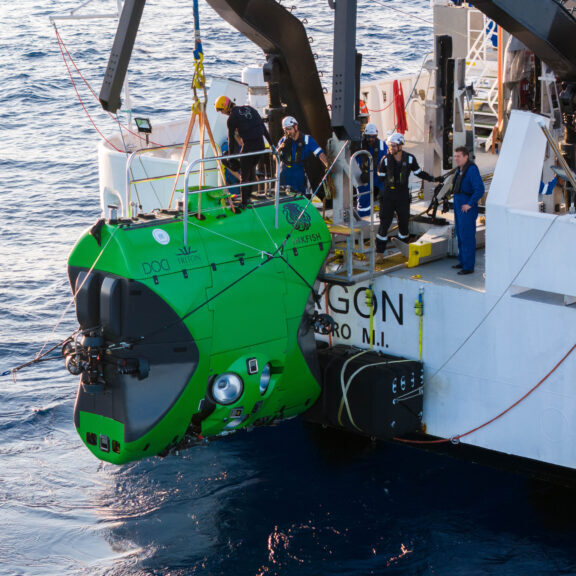

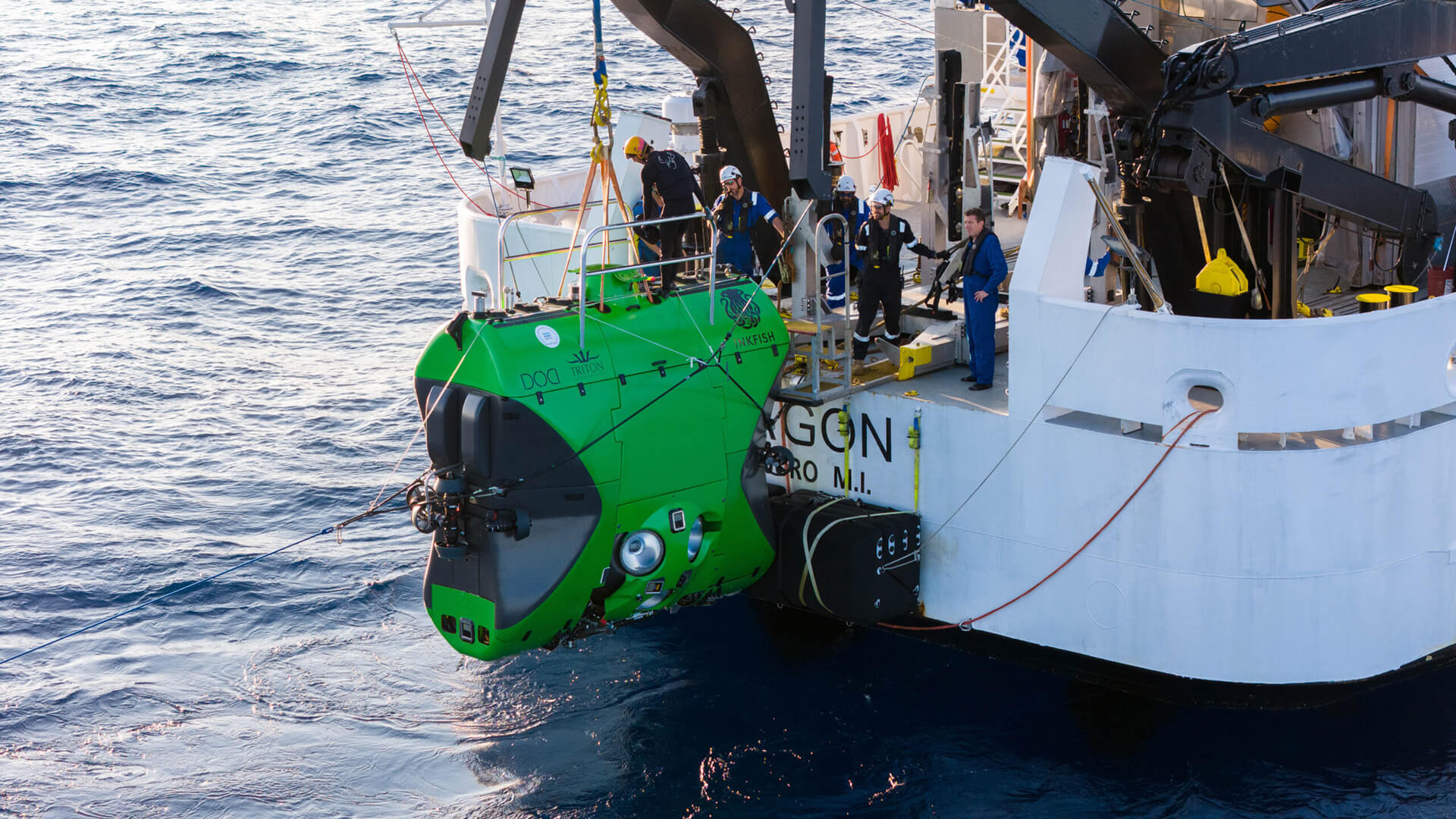

Inkfish, a marine research organisation dedicated to exploring the world’s deepest, unexplored areas of the ocean, recently turned to Base Materials to replace the current buoyancy modules on its full ocean depth-rated, human operated submersible.

Formerly ‘DSV Limiting Factor’, the two-person, 12-tonne vessel was previously used for The Five Deeps Expedition, the first successful manned descent to the deepest point of each of the world’s five oceans.

Unique in that it is one of only a handful of submersibles that is DNV-certified for extensive and repeated dives at full ocean depth for oceanographic exploration, in replacing its current buoyancy system, it was essential that Inkfish had a partner that could provide DNV-approved buoyancy materials.

As the first syntactic foam subsea buoyancy materials manufacturer to achieve full DNV type approval and DNV Approval of Manufacture across its entire portfolio of Subtec® buoyancy materials, Base Materials provided exactly that. The proposed buoyancy system will be manufactured from the organisation’s Subtec® 11500, a low-density high-performance syntactic foam buoyancy material, which is qualified for use in seawater depths down to 11,500 metres.

With densities from 400 – 650 kg/m³ and grades to suit a range of seawater depths from 2,000 metres to 11,500 metres, Base Materials’ Subtec® buoyancy materials comprise high-grade hollow glass microspheres and a novel thermoset polymer matrix, producing ultra-high strength-to-weight characteristics with excellent water ingress resistance. From water absorption to hydrostatic crush pressure, density to uniaxial compressive strength, and more, the range is rigorously tested in-house.

Preparing for a deeper, busier, greener future

The transition to renewables isn’t just changing the way we generate power - it’s reshaping the entire subsea landscape. Offshore wind is heading into deeper waters, electric ROVs are replacing hydraulic systems, and operators are returning to older fields with renewed interest and upgraded technologies.

In this context, ensuring the quality and certification of subsea buoyancy materials is no longer a box-ticking exercise - it’s a strategic imperative. As offshore infrastructure becomes more ambitious and more complex, only those components with proven performance, verified through independent testing and certification, will meet the evolving demands of a deeper, greener future.

First published in PES Magazine, 2025.