Our commitment to sustainability is deeply rooted in the 4R principles: Reduce, Reuse, Recycle, and Recover.

These guiding principles shape our approach to environmental responsibility, driving us to innovate and implement practices that reduce our impact on the environment.

Reduce

Our dedication to reducing environmental impact begins with supporting you to design with sustainability in mind. Our specialist mass casting and casting to size services optimise material usage, reducing material waste compared to traditional methods of blocking up tooling board and CNC machining to shape.

By integrating bio-based raw materials that come from renewable plant-based sources into our tooling board formulations, we reduce our reliance on fossil-based raw materials.

We offer epoxy tooling boards for direct-to-part tooling in carbon fibre production. This means you can reduce the number of steps in your manufacturing process by removing the need for a mould tool and improve efficiencies by enabling components to be manufactured directly from the master model or pattern.

Reuse

Durability and longevity are at the heart of our product design philosophy. Our durable High Density PU tooling boards are engineered for repeat use*, enabling you to extend the product lifecycle and reducing the need to replace tools made from standard tooling materials.

We promote the repair and reuse of your tooling to maximise longevity and reduce waste. For example, offcuts from tooling boards can be bonded together and tools and patterns skimmed and repurposed for smaller projects to maximise usage, minimise waste and reduce the use of virgin material.

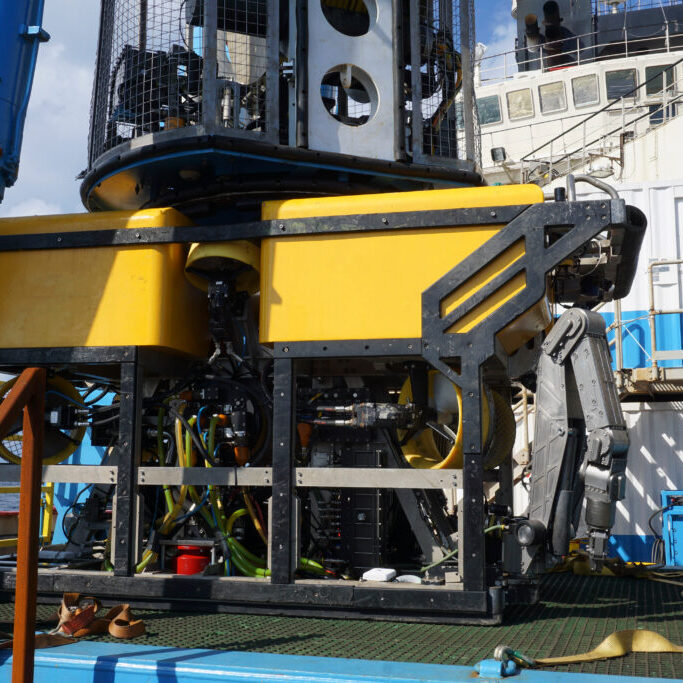

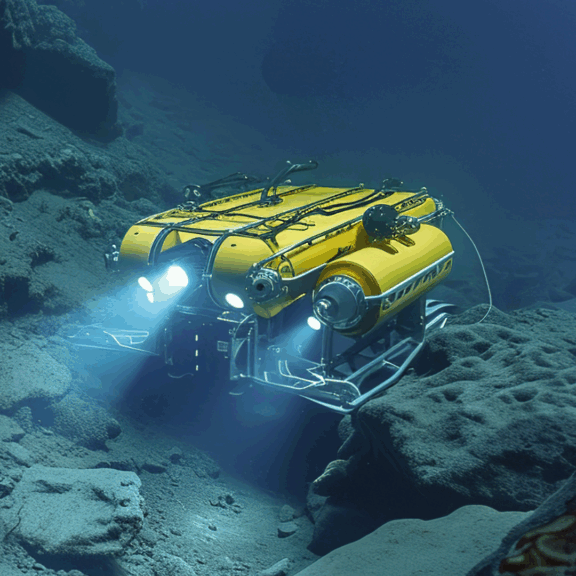

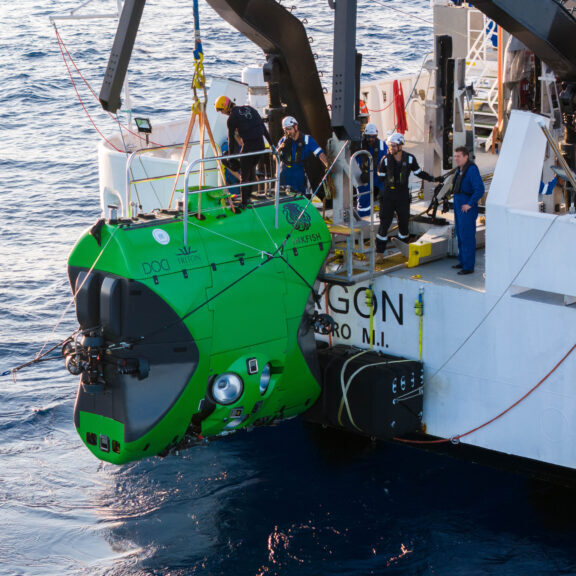

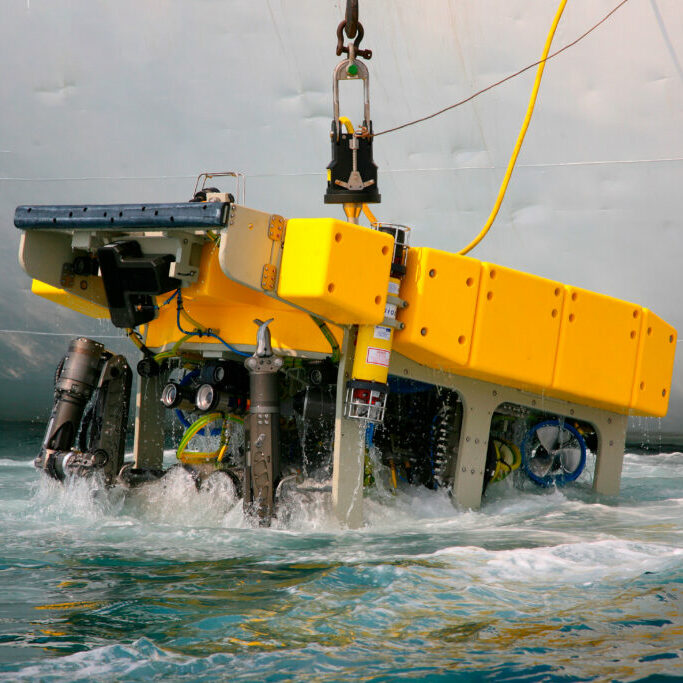

Our buoyancy repair and refurbishment service is specifically designed to extend the life of your buoyancy modules, giving them a second life to ensure maximum usage and return on investment.

By prioritising materials that maintain their integrity over time, we support you in effectively managing your resources and extending product lifecycles.

Recycle & Recover

Our innovative Recast® material provides an alternative solution for your unwanted patterns and moulds. We take back pre-agreed volumes of your used patterns made from our tooling board materials, process them at our facility in Leicester, UK, to make new novel materials and reduce waste going to landfill.

Most importantly, not only is this technology creating a recycled material; it has another unique quality – the new recycled material can also be re-processed multiple times, further reducing waste to landfill.

Recast® is currently open as a pilot scheme for our UK-based customers, while we continue to develop the service. If you’re interested in taking part, let's talk!

To us, the 4 R principles are more than guidelines—they are integral to our operations and ethos. Through continuous innovation and dedication to these principles, we are evolving our practices and improving our impact on the environment.