Engineering precision for next-generation unmanned vehicles with ElevonX

A partnership delivering accuracy, stability and future-ready aerospace tooling

Key Products

Challenge

In the rapidly evolving world of unmanned aerial vehicles, innovation is driven by precision. For aerospace pioneers like Slovenian-based ElevonX, delivering fixed-wing Vertical Take-Off and Landing (VTOL) drones and unmanned vehicles that perform flawlessly in critical environments – from humanitarian logistics to defence – requires components that meet the most exacting technical standards.

With projects that include delivering medical supplies to remote areas in partnership with the United Nations, ElevonX is committed to creating bespoke systems tailored to highly specific customer requirements. So, when the company commenced a new project in collaboration with a leading developer of advanced remote defence vehicles, they needed a tooling solution that could meet the most stringent dimensional and stability requirements.

For this mission-critical project, ElevonX was tasked with producing high-precision carbon fibre components for remotely-operated ground vehicles. These components demand exceptional dimensional accuracy and thermal stability to ensure performance under demanding operational conditions. Previous tooling boards had failed to maintain dimensional integrity during machining – an unacceptable risk for components destined for defence applications. ElevonX needed a tooling material with a very specific coefficient of thermal expansion (CTE) and in-situ stability. Only one material met the challenge.

Solution

ElevonX was introduced to Base Materials through a trusted industry recommendation, recognising the unmatched reliability and expertise Base Materials brought to the table. More than just a supplier, Base Materials offered peace of mind through deep technical know-how and a tooling material that had already earned a reputation among aerospace professionals.

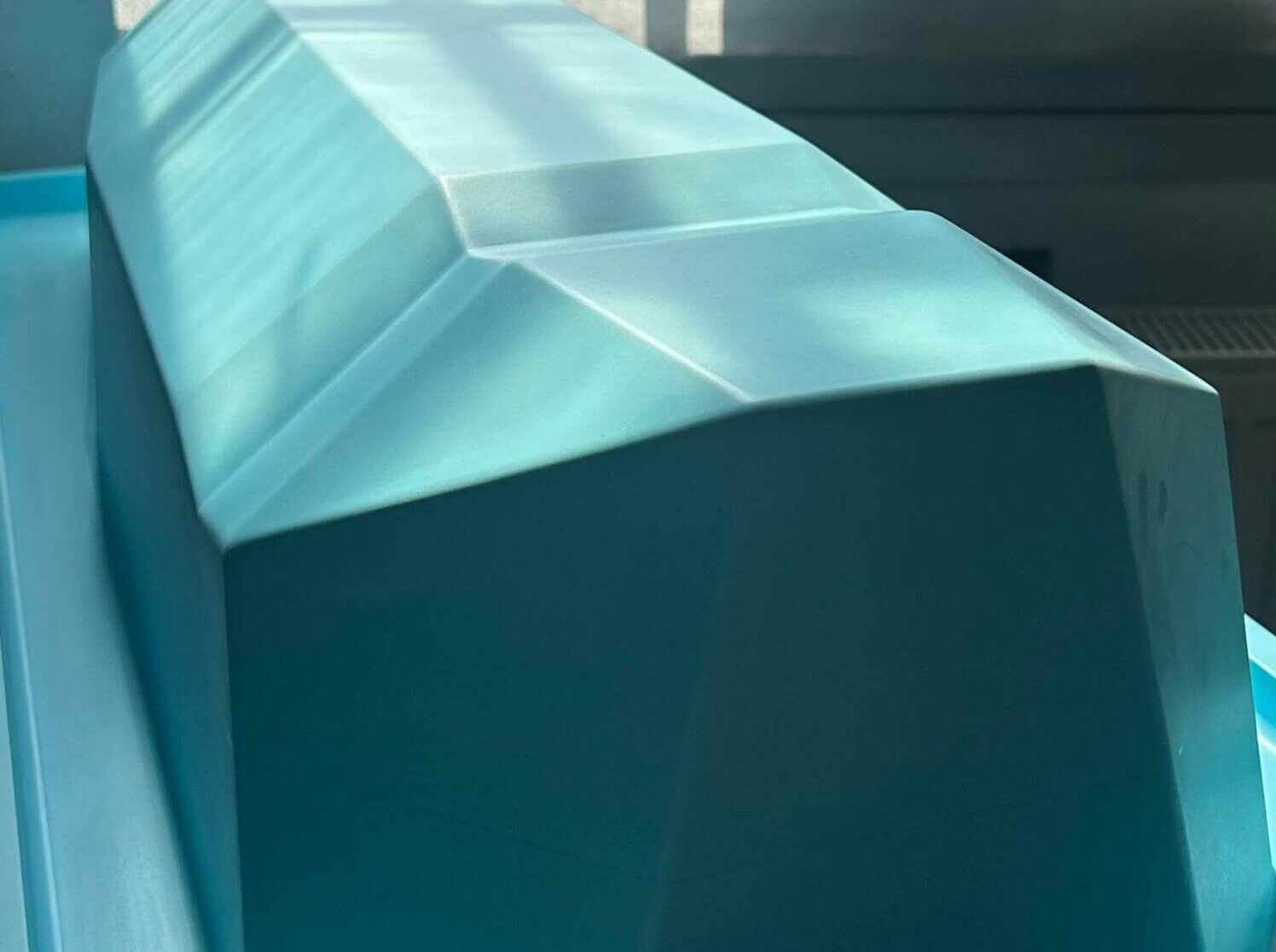

ElevonX selected BE978, Base Materials’ market-leading epoxy tooling board, known for its excellent dimensional stability, inert surface, and low CTE. Designed for medium-temperature use, BE978 is widely regarded for its performance in master models, patterns, jigs and fixtures – and proved to be the ideal solution for ElevonX’s high-tolerance carbon fibre components.

Thanks to BE978, the company achieved the precise measurements and structural stability needed for the project. Based on this success, ElevonX has confirmed that Base Material’s tooling board will now be its material of choice for future projects.

Their next collaboration? A new wing design for ElevonX’s proprietary VTOL platform. With a 4.4-meter wingspan and performance goals focused on extending flight time, the project will demand accurate, reliable master models. In this highly competitive market, even marginal gains in endurance unlock significant commercial opportunities – and the right tooling materials are a critical part of that equation.

“Base Materials stood out not just for their tooling board, but for their knowledge and technical support. We were told they were the best – and now we know why. BE978 delivered everything we needed in terms of dimensional accuracy, thermal stability and ease of machining. It’s the best tooling board we’ve used, and we’ll continue to work with Base Materials for future projects.”

Matjaž Brank

Composite Production Manager