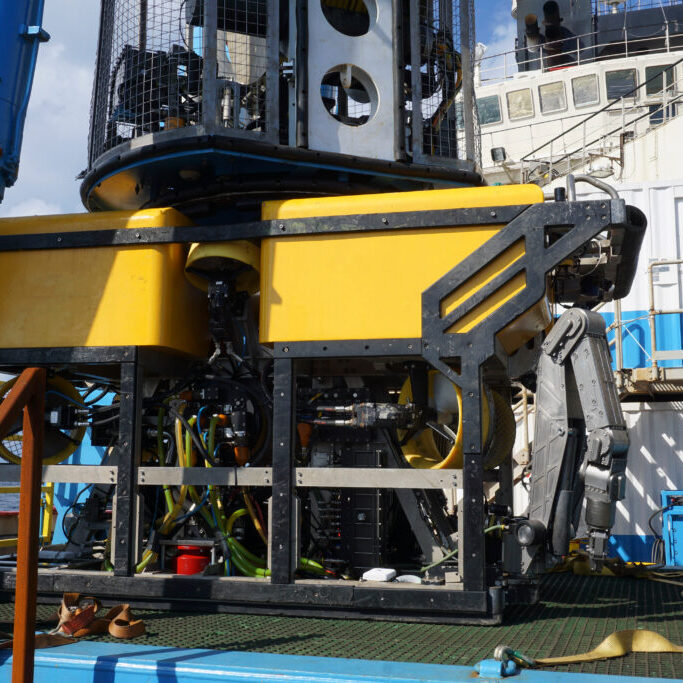

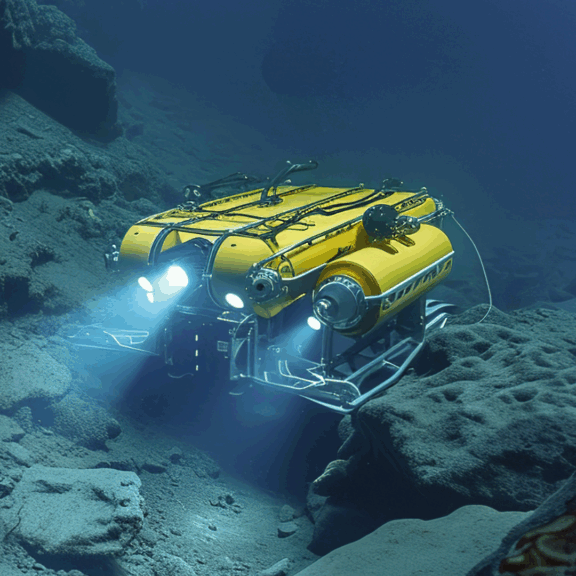

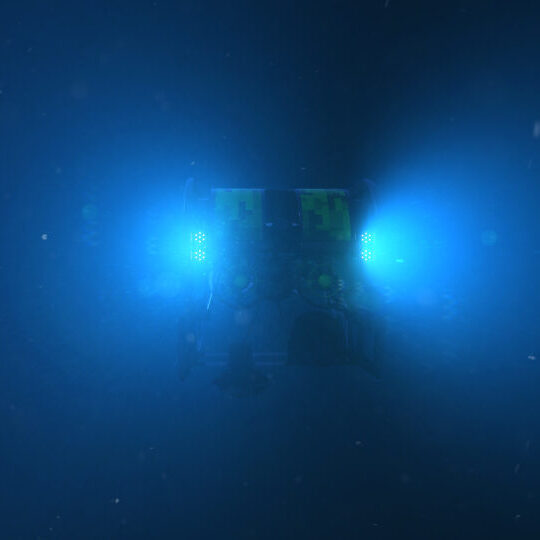

The global offshore remote-operated vehicle (ROV) market is burgeoning. But, with a growing demand for deep sea exploration, ever-increasing operational costs, and more stringent environmental regulations, ROV owners and operators face significant challenges. As a result, ROV owners and operators must future-proof the performance of their ROVs efficiently, cost-effectively, and sustainably.

ROV buoyancy modules are mission-critical equipment for the facilitation of subsea exploration, from offshore energy (renewables and oil & gas), and oceanographic research, to defence applications, search and rescue vehicles and more. Taking a whole-life approach ensures high-quality buoyancy modules perform as required in situ for their intended service life. That’s because a whole-life approach to ROV buoyancy modules – one that realises the value in repairing and refurbishing old, damaged, and worn modules, rather than simply buying new - will significantly reduce capital expenditure, optimise return on investment, and decrease waste to landfill.

In short, ROV buoyancy modules that perform for the duration of and beyond their intended life are both a better investment and better for meeting net-zero targets.

Building the case for repair and refurbishment

The rapid pace of technological advancements in subsea equipment requires continuous investment to stay competitive. But, on average, the cost of a new set of modules to an ROV owner or operator can be anywhere between 64,000 to 1.3 million USD and beyond for specialist applications.

This represents a significant investment which, caused by ever-advancing subsea buoyancy materials and manufacturing processes, simply isn’t a feasible option for all. Many ROV owners and operators already have strained capital resources and are exacerbated by economic volatility in industries like oil & gas, which heavily utilise ROVs.

As a result, owners and operators must consider repairing or refurbishing existing ROV buoyancy modules as a more cost-effective alternative to purchasing new ones, to ensure they continue to meet original specifications and operational industry-recognised standards. Extending the service life of existing equipment, which is as critical across the subsea buoyancy sector, as it is any other, presents the opportunity for owners and operators to increase return on expended assets.

Repair and refurbishment services offered by leading buoyancy module materials manufacturers, which include anything from repairing scuffs to recoating the protective skin to enhance abrasion and impact resistance, can help to reduce capital expenditure by as much as 40%. This represents a significant opportunity to maximise operating profits and optimise return on investment.

One essential consideration that can determine whether repairing and refurbishing your existing modules will maximise return on investment, is whether your existing buoyancy modules are manufactured from a material that is fit for the purpose. For instance, macrosphere-based syntactic foam systems was used to create what are now legacy, lower-cost buoyancy module systems. However, these materials generate a relatively low buoyancy per cubic metre, are highly prone to significant loss of buoyancy from minor damage and are difficult to effectively refurbish and repair due to the nature of their manufacture. As a result, while macrosphere-based syntactic foam systems are still used today for shallow depths or large volume applications and where they are less likely to be damaged in operation, for example, on a trenching ROV, the majority of the ROV industry utilises pure syntactic foam systems which are far more durable, and importantly, when repaired and refurbished enable greater value to be realised.

In addition to the cost case for repairing or refurbishing today’s syntactic foam ROV modules, the process of doing so is approximately 25 to 30% quicker than the manufacture and delivery of new modules, an essential consideration particularly for explorations in remote environments. This enables ROV operators to potentially reduce overall operational costs, by refurbishing existing modules where possible, rather than buying new modules at a premium. One way to combat the potential downtime caused by the delivery of new modules, particularly for time-sensitive projects, is having a refurbished set on-site as a spare.

Facilitating ROV manufacturer repair and refurbishment revenue

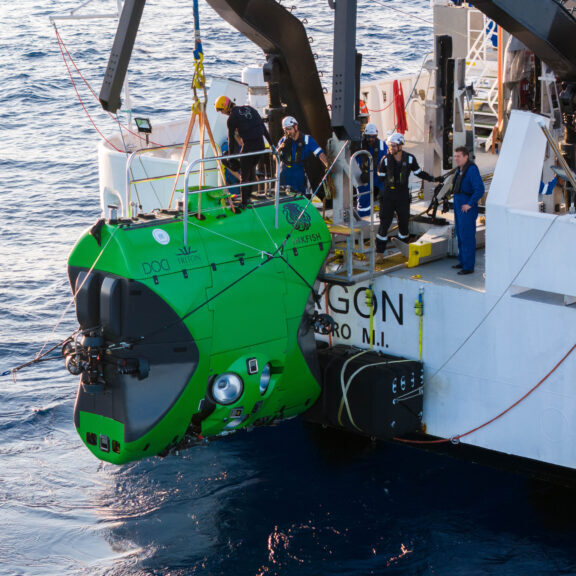

From a monetary perspective, the benefits not only lie with owners and operators. Repairing and refurbishing existing ROV buoyancy modules offers ROV manufacturers a valuable secondary revenue stream. By reselling refurbished vehicles, manufacturers can leverage their existing systems to tap into the demand for a more cost-effective alternative to a completely new ROV.

This diversification can mitigate the impact of current and future fluctuating sales of new units, providing a steady income stream even during market downturns, and helping to build a more resilient and diversified business model that can enable manufacturers to become a one-stop-shop for both new and refurbished equipment. While ROV operators benefit from a solution that removes the need to buy new and the required associated investment.

Creating an ROV module circular economy

Sustainability is no longer an afterthought. It is an increasingly important consideration in the ROV space for manufacturers, owners, and operators alike, driven by a combination of motivational drivers, including reputation and a commitment to reducing emissions and adapting to the impacts of climate change as part of The Paris Agreement.

The journey towards net zero carbon emissions has seen a growing emphasis on the development of ROVs that have a minimal impact on the environment, whether from the utilisation of recyclable materials, low energy production processes, or the incorporation of electric and hybrid propulsion systems.

However, for ROV buoyancy modules specifically, there are significant sustainability benefits to be realised in prioritising the maximisation of the service life and reduction of the replacement of modules, ahead of short-term performance. This is because in addition to reducing capital expenditure, giving existing modules a second life where possible, which can be as many as five years of further use, reduces waste to landfill. So much so, if even just 1% of the current ROVs in operation globally were decommissioned, this would represent approximately 30 to 40 cubic metres of syntactic foam going to landfill.

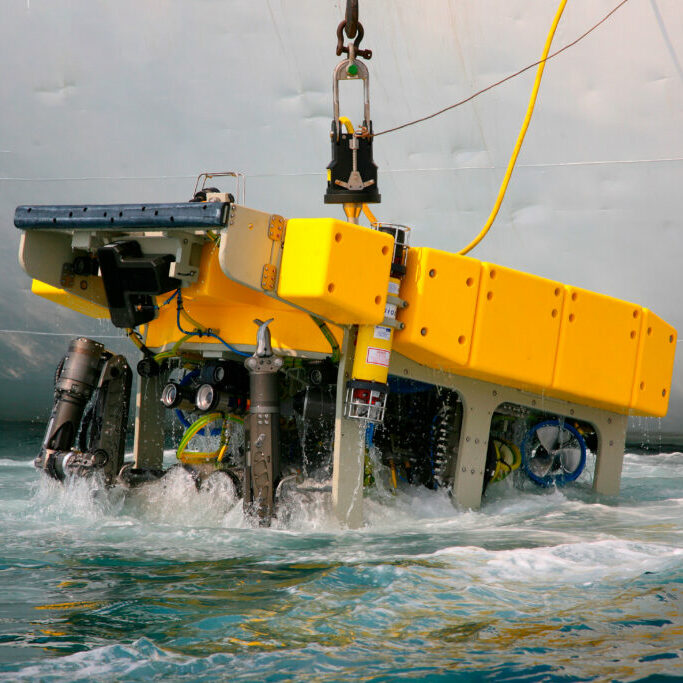

Case study: Extending the life of a 15-year-old ROV

A global ROV Original Equipment Manufacturer (OEM) recently turned to Base Materials to extend the operational life of its customer’s 15-year-old ROV.

The company’s refurbishment and repair service extended the service life of an old, damaged, and worn set of buoyancy modules by up to five years while reducing waste to landfill and removing the need to purchase new modules.

In just a matter of eight weeks, from its 10,000 square feet state-of-the-art production facility in Birmingham, UK, Base Materials replaced module metallic inserts to allow the fitment of new equipment to the ROV module and enable attachment to a new frame. Additionally, it added customer stencils and markings to the ROV, along with non-slip coatings on the buoyancy modules to ensure the safety of operatives walking on the equipment.

Following the successful replacement of the modules, the OEM and their customer have requested Base Materials to refurbish and repair a second set of buoyancy modules.

The way ahead

ROV buoyancy modules are mission-critical equipment, and is imperative that ROV manufacturers, owners and operators realise the various economic and environmental benefits of giving old, damaged, and worn modules a new lease of life, rather than simply buying new.

From optimising return on investment to meeting organisational net zero targets and more, there is undeniable value to be realised for all in enabling ROV modules to perform for the duration of their intended life and beyond.

First published in Ocean Robotics Planet Magazine, 2024.