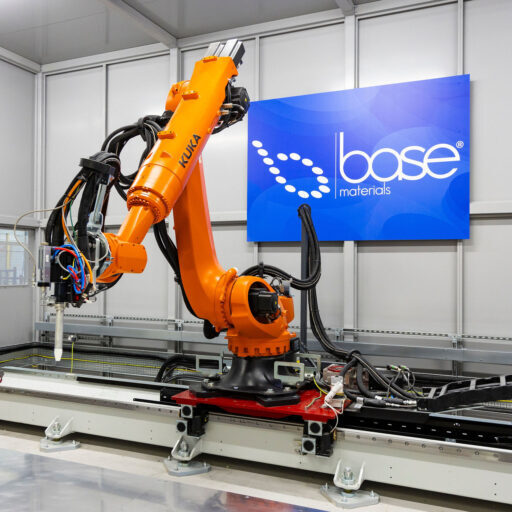

Working with you, we can create simple or complex near-net-shape tooling, at our facility in Leicester, UK, ensuring your tool is as close to the final shape and size as possible. This reduces the amount of post-production machining and finishing required, saving you time and resources and resulting in less waste material.

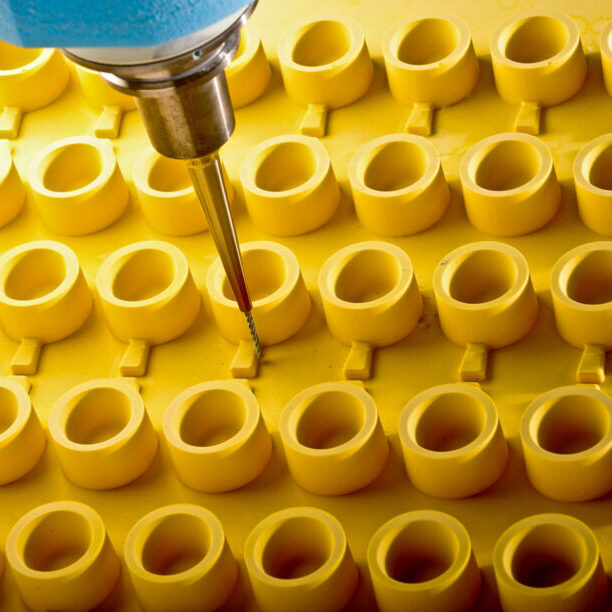

Using your CAD drawings and designs, first we create a bespoke negative mould for your tool using one of our industry-leading, low-density polyurethane materials. We then select the system for casting based on your application and requirements and use the negative mould to cast your near-net-shape tool.

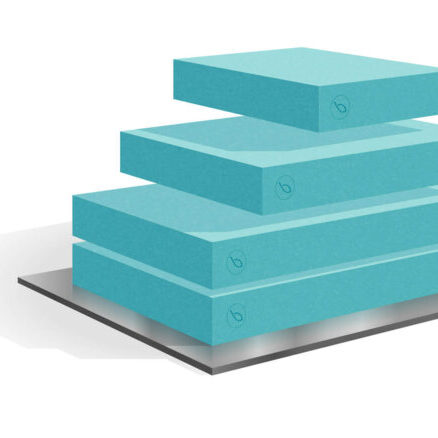

We have a range of materials available for mass casting applications and near-net-shape tooling, with densities ranging from 600 kg/m3 to 1,700 kg/m3.

FIND THE RIGHT PRODUCT FOR YOUR APPLICATION WITH OUR INTERACTIVE SELECTOR TOOL

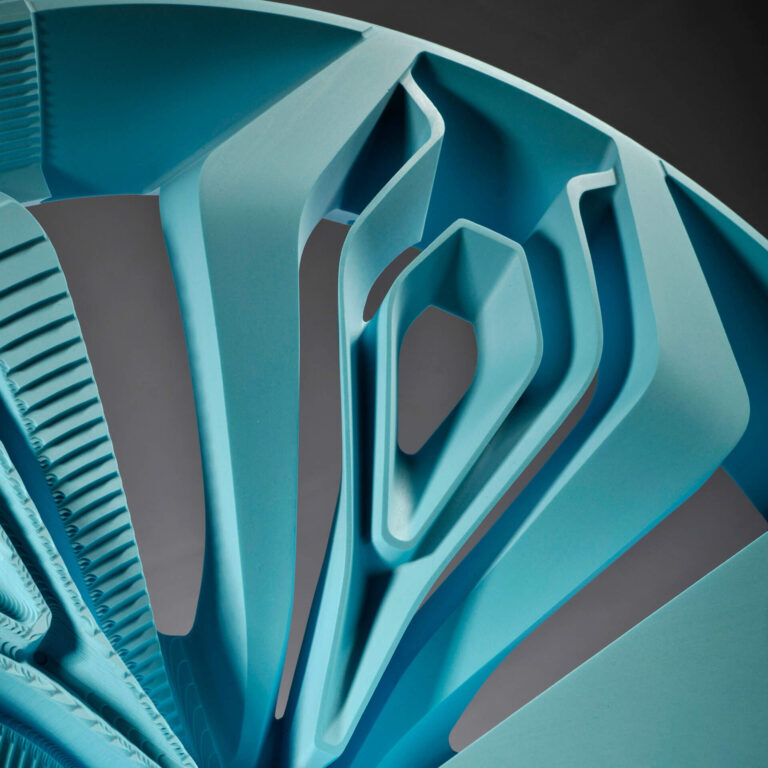

Our mass casting service offers increased flexibility when designing and producing complex geometries and intricate details.

FEATURES & BENEFITS

- Reduction of waste material through near-net-shape casting

- Reduced production costs at near-net-shape tool needs less machining

- Tool is cast as a single piece, there are no visible bond lines

- Processing savings as service is outsourced

- UK-based manufacturing service

APPLICATIONS

- Complex geometry tooling

- Intricate detail tooling

- Single-piece tooling

- Large scale tooling

- High-temperature applications