key Considerations

A crucial aspect to consider when selecting the right material is the physical properties:

Density - the higher the density the more robust the board, meaning finer details are machined easily. Lower-density tooling boards are ideal for creating models and prototypes as they are easy to shape.

Temperature and Coefficient of Thermal Expansion (CTE) - The lower the CTE, the less the tooling board will expand as temperatures increase. Choosing a material with low CTE ensures precision and consistency in the mould.

Dimensional stability – Tooling boards with excellent dimensional stability reduce the risk of expansion or shrinkage and maintain their original shape throughout manufacturing and subsequent use.

Surface finish – the tool's surface finish directly impacts the look of the final part. Materials that boast a great surface finish remove the risk of defects and improve the overall durability of the tool.

Benefits of using high-quality tooling boards

High-quality tooling boards provide a range of benefits that make them a reliable choice for manufacturing models, moulds, patterns, fixtures, gauges, and metal forming tools.

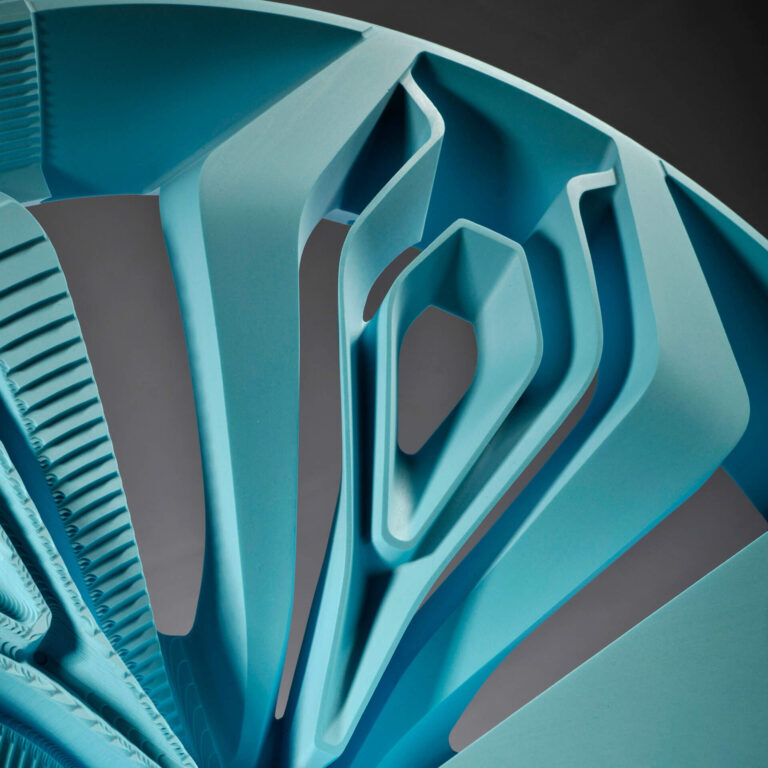

Precision and Dimensional Accuracy – Consistent material properties help to ensure that every detail you machine is transferred to the final part. A high-quality tooling board keeps tolerances tight and helps reduce errors during manufacturing.

Superior Surface Finish – Premium tooling boards are engineered for fine surface quality, minimising the need for extensive post-processing. This leads to smoother moulds and patterns, ultimately resulting in better-looking, more durable finished components.

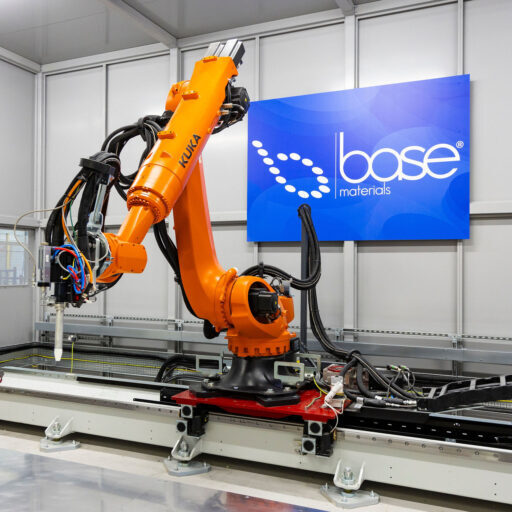

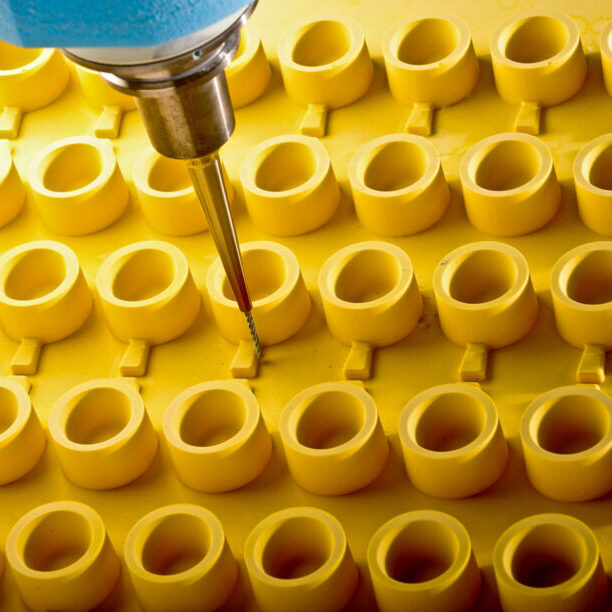

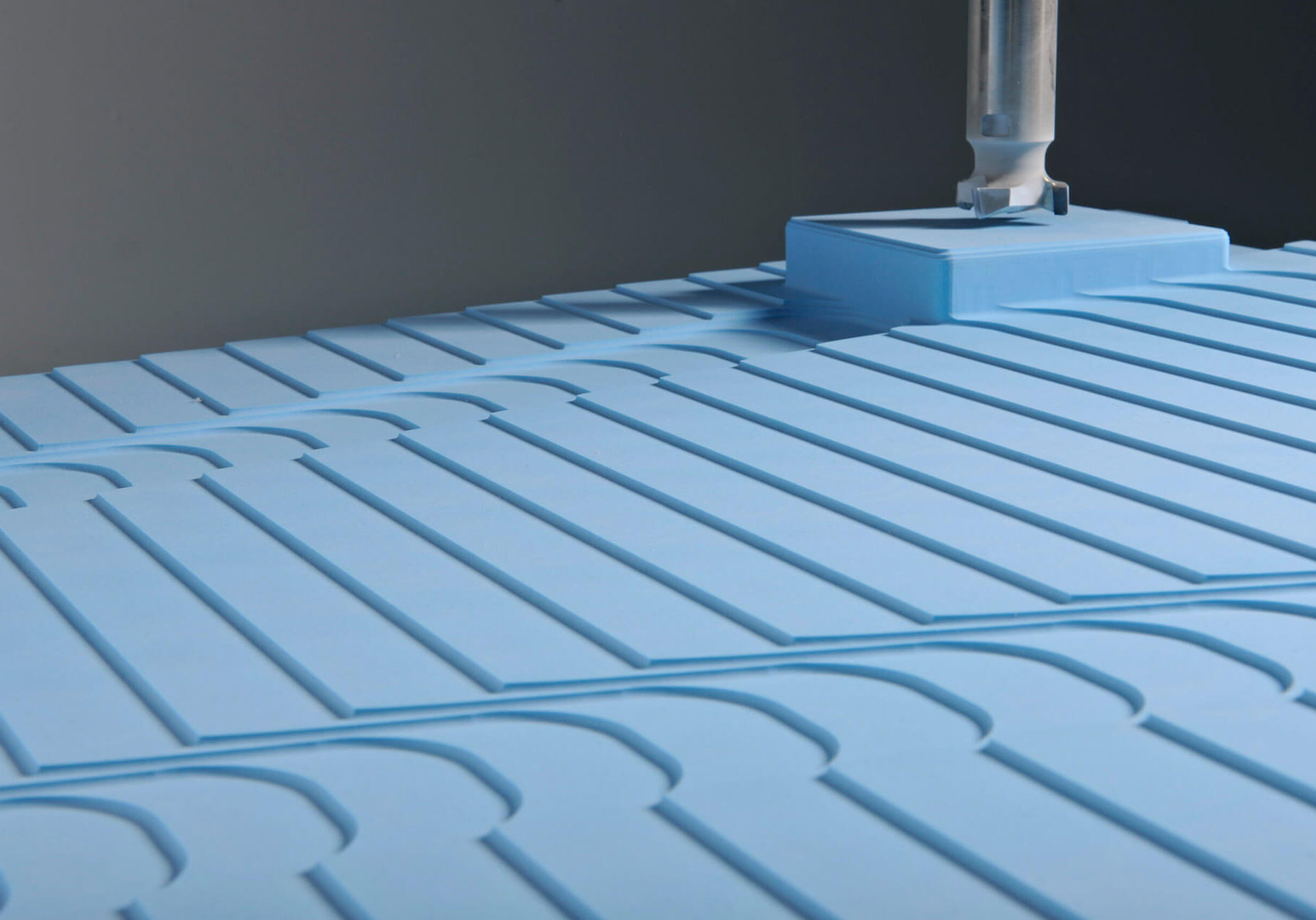

Outstanding Machinability – Our tooling boards are formulated for ease of use, whether you are working by hand or using CNC machinery. The uniform composition reduces tool wear, dust generation, and machining times, leading to a more efficient workflow.

Durability and Longevity – High-performance tooling boards withstand repeated use, helping maintain the structural integrity of your tools and prolonging service life.

Cost-Effective Production – Reliable material quality and minimised waste translate into cost savings. Reduced rework, fewer failed parts, and extended tool life all contribute to economical manufacturing, helping you get the best return on investment.

FIND THE RIGHT PRODUCT FOR YOUR APPLICATION WITH OUR INTERACTIVE SELECTOR TOOL

Your Application

Tooling board selection depends on your application.

Epoxy is the material of choice for advanced composite applications where low CTE, dimensional stability and excellent surface finish are essential.

Polyurethane offers a cost-effective alternative for design, styling and prototyping projects, vacuum forming, thermoforming, and manufacturing jigs and fixtures. High-density materials offer a solution for hammer and metal forming, foundry patterns and Reactive Injection Moulding (RIM).

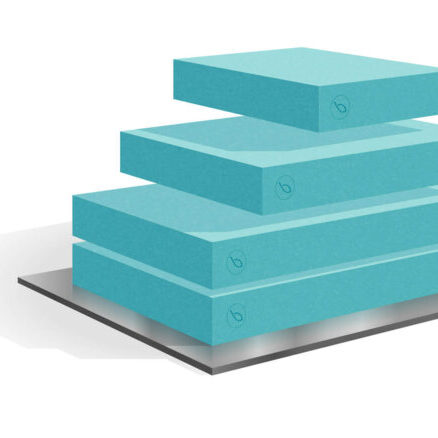

Our simplified tooling board process makes it easy to understand how tooling boards are used.

Epoxy Tooling Board

- Superior dimensional stability

- Low coefficient of thermal expansion (CTE)

- Excellent surface finish

- Suitable for direct-to-part manufacturing

- Material of choice for high-temperature applications up to +190 OC

- Inert material that is chemically compatible

These boards deliver reliable dimensional accuracy and fine surface quality, making them ideal for situations where durability and a high-quality finish are non-negotiable.

Epoxy tooling boards are often the go-to for demanding environments where thermal stability and surface precision are critical. They can be used confidently in settings that require robust, reliable performance, making them a staple in aerospace, automotive, and industrial design.

Polyurethane Tooling Board

- Lightweight and versatile

- Cost-effective alternative for design, styling and modelling applications

- Easy to work with

- Can be hand styled and CNC machined

- Excess material flakes rather than dusts

- Wide range of densities available

Polyurethane's consistently good processing and machining properties ensure efficient model and mould production without sacrificing quality.

Polyurethane tooling boards are a mainstay in model shops and studios for good reason: they’re compatible with a wide spectrum of creative and technical projects. Whether you’re roughing out automotive styling models, prepping architectural prototypes, or crafting display pieces, these boards offer flexibility and ease of use.